-

Content Count

557 -

Joined

-

Last visited

-

Days Won

21 -

Feedback

0%

Posts posted by colins

-

-

11 hours ago, Snowman22 said:I wish I was here to write a different review, but I'm not…

For all of you who don't want to be bothered with the details…The machine seems like it has the potential to be everything it's advertised to be, but might not be worth the risk due to its cost. It leaves a great finish on the blade, it's square, and skates well.

The customer service is subpar at best. They are responsive, but will not do anything beyond the black and white warranty process. So buyer beware, unless you can stomach throwing away the machine a day after the warranty expires in a year.

Long story short, the wheel I received with the machine was defective and was completely wasted after using roughly 30% of its useful life in approximately 2weeks. Instead of just sending a new wheel out, I received a credit for $37.67.

~~~~~

Now for some of the details on how I ended up where I am and why I'm so disappointed with the whole situation.

I originally purchased the machine and the day I received it ended up on their website to look at accessories and found there was a new $100 off deal running. Considering I just purchased and received the machine, I thought they might honor the deal to a new purchase, no such luck. At the end of the day, I get it, it's a business, and I purchased it at the price I did, so water under the bridge at this point.

Within the first few uses I felt the machine was making contact with too much pressure and causing a very slight chatter. Not visibly noticeable, but sounded a little strange. After contacting Sparx they offered to have the wheel sent back and a exchanged. I didn't feel the issue was truly a problem because visually it looked ok and skated fine. They instructed me to move the contact point down on the blade to lower the pressure which seemed to alleviate some pressure and make a smoother pass. In hindsight, I should have sent the wheel back day one. I just didn't want to waste time and money shipping a good wheel, and didn't want to be without the brand new sharpener I just spent almost a thousand dollars on.

Over the next two weeks I sharpened all 5 sets of my own steel, along with a few sets for people I skate with. I didn't count passes used but three lights were out when the wheel finally gave up completely. The vibration came back 5 times as bad as it was in the beginning and I knew something was not right. I ended up using a sharpie to mark an entire blade and the recommended passes, the results are one of the pictures attached, but as you can see it didn't cut the blade at all.

Before I realized the wheel was not working out as intended I purchased two additional wheels, one backup to the original hollow and a new hollow to test. So at this point I'm well over a grand invested into this thing.

After reaching out to Sparx I used the original return label to ship in the defective wheel for inspection, and to no surprise it was "Defective" This is when I was offered the pro-rated amount in an online credit. Does this approach meet the minimum documented warranty on the website, yes, but does it make me feel great about a company I just spent so much money with on a new product in the market, not at all.

After receiving the additional wheels I purchased after the initial purchase it became obvious the original wheel was defective from the start. The new wheels leave an absolute perfect finish and the machine runs as smooth as you could imagine. It's frustrating because all the time before was wasted because I didn't have a baseline to compare to. Manufacturing/Mechanical defects are a part of life and are unavoidable.

In the end, the issue at hand for me in this whole ordeal is the principle of it all. If I had had this machine for a long time, used a significant portion of the life of the wheel, the defect was marginal or questionable, had I ever had the machine actually ever working properly, I may understand the pro-rated return. I however never had the machine working properly in the beginning and ended up re sharpening 5 sets of steel because I don't know when it started to leave a bad edge.

I digress….

Picture Links, I couldn't get them to link properly with the insert function.

Any theory on what caused the abrasive coating to strip off the wheel so quick? Was it a manufacturing defect I wonder, or did the wheel come in contact with a set of steel it didn't like?

Sounds like you got off to a rough start which always sucks with a new product. I'm on my 4th wheel now, and so far so good - haven't run into anything like that yet.

colins

-

44 minutes ago, gogovs said:Well, I've seen much worse. One line off is probably not noticeable, you're at about a line and a half. A few clicks should get you dialed right in - just follow the instructions that came with the edge checker.

colins

-

46 minutes ago, Indo16 said:When I first switched to FBV I was skating on 5/8" ROH so I went with a 90/1. I've done well with it for the past year, but I think I want to try something with a little more bite. What is the difference in feel between a 95/75 and a 100/50? Chadd, I think you said you put most of your guys on 95/75. What is their range in size? I'm 5'10" and fluctuate between 170 and 176 lbs. Nowhere near me does FBV, so I can't do a test run, and Blackstone's shipping cost or $150 minimum makes it pricey to try something I may not even like. And $68 is pretty pricey to begin with.

Also, when switching between hollows (going from ROH to FBV or FBV to different FBV) how many total passes should I do to make sure I've completely changed it? I have an X-01.

Have you tried the Sharpie test? You can use a Sharpie to blacken the hollow, and then do as many passes necessary to completely remove the marker from the blade.

-

32 minutes ago, IPv6Freely said:You just had to reply to their email about it. They sent it to all customers January 16th.

Nope, all customers.

I received the email on Jan. 29th. It was only for X-Grind ring customers:

Replacement Filter Offer for Existing X-Grind Ring Customers

For those customers who had previously purchased a X-grind ring, we extended to them an offer for a free filter as a courtesy and reminder of the importance of Removing and Emptying the Dust Tray and Changing the Air Filter. (If you had not previously purchased a X-grind ring, you were not on this list… we love all of our customers but this offer is limited to this select group).

colins

-

On 3/12/2017 at 9:17 PM, Healthyscratch said:Just going to flat out ask this...

is it worth it to purchase one of these as it stands or should I wait until some kinks have been worked out in future generations?

Reviews seem to be a mixed bag. Their online forum has a few people presenting some concerning issues.

I think Sparx has shipped over 3000 units now. If you look at the volume of questions/issues on their online forum, as a percentage of users it has to be some very low number. Imagine 3000 Blademasters or Blackstones going out, the majority to folks who've never sharpened a pair of skates before...

-

-

8 minutes ago, IPv6Freely said:Good god. Did you use the xgrind ring to fix that? Or just a ton of regular ring passes?

I don't have a xgrind ring, but after about 7 or 8 passes it was pretty respectable:

These were inexpensive skates just being used for some outdoor casual family skating. Still though, I don't know if you could trust turning or changing direction at all on those edges as they came out of the Canadian Tire sharpening.

colins

-

Sharpened these blades last night. Worst I've seen so far. These were apparently done on a DupliSkate machine at a local Canadian Tire store. I don't blame the machine, obviously there must be some adjustments on it the kids who operate it aren't familiar with or just don't care about.

Here's what they looked like when I got them.

I also learned that the Sparx is compatible with Disney skates. Ground breaking...

colins

-

1

1

-

-

1 hour ago, bootsmagee said:Just wanted to throw an observation out there; this may be common knowledge to those with experience.

I recently received the edge checker from Sparx. I picked one up over the holiday since they offered a sale price. I've used it on about 6 pairs of skates run through the Sparx and figured out something interesting. On the first few skates, I was able to confirm that the Sparx was adjusted properly and the edges tested very close to perfect; off by no more than a single engraved line thickness on the edge checker (not a line-to-line "bar" as in like .06", but actual engraved line thickness as in .01-.02") Then I sharpened my GF's skates and a pair of small child's skates for a friend. I noticed that these were testing way off when using the edge checker. I determined that it must be from the lower quality steel of the cheaper skates which isn't actually flat, even on the vertical face top-to-bottom. When clamping the edge checker and holding it up to a bright light, I could see that the banking edge would not sit flush with the steel; there was a visible gap along it's face and the edge checker could be rocked side to side making the gap open and close top-to-bottom. Flipping the edge checker 180-degrees to bank on the other side of the steel helped in one case, but not the other.

Yes, and some higher quality steel like polished CCM Hyperglide and Speedblade Black will exhibit the same issue - sidewall inconsistencies in the steel/coating will throw off the Sparx edge checker (and any edge checker that relies on a good flat sidewall in order to establish a 90 degree angle between the sidewall and edges to measure against).

I know they point this out in the manual/instructions for the edge checker, but who reads those?? :-)

Great feeling though when you get those edges dialed in to measure bang-on the line heel to toe and toe to heel isn't it? Everyone who has a machine should have an edge checker of some type that they trust so you're not just relying on the calibration tool that comes with the Sparx to get it 'close enough'.

colins

-

On 12/28/2016 at 4:24 PM, DarkStar50 said:

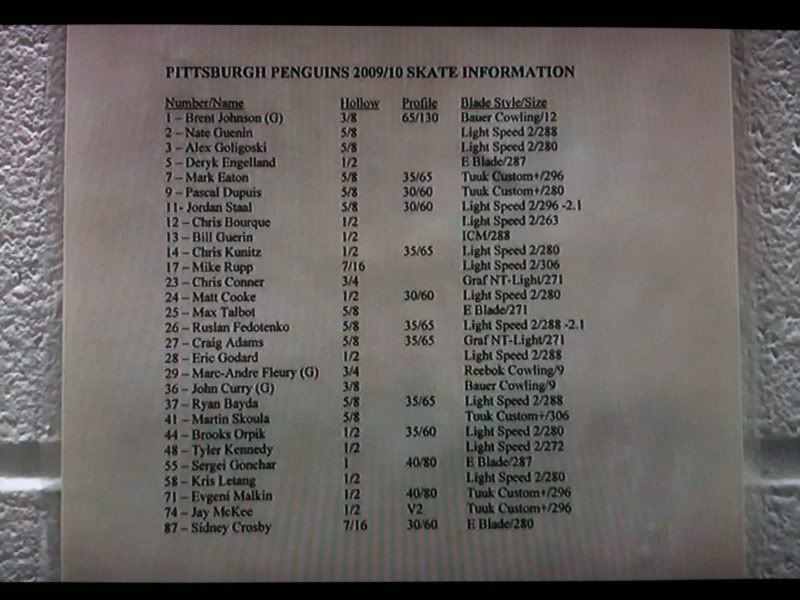

Only the goalies and Kessel below 1/2". An older chart from a few years ago had Crosby at 7/16", now 9/16". I wouldn't be surprised if McDavid is above 1/2" for more glide.

From an older post in another thread:

Interesting that back in 2009/2010, 13 players (leaving out goalies) were on 1/2 or deeper. Fast forward to this year, and only 4 remain with that much bite or more. It's seems like the EQM default shifted from 1/2 to 5/8ths for the players that 'don't care'.

What's the 'SS' mean on the current year chart after 'LS3' on Kunitz and Coles blades? Step Steel maybe? Or do they have a Stainless Steel coating on their LS3?

colins

-

35 minutes ago, DarkStar50 said:Write him a fan letter ! That's what we did when we were kids.

lol! I'll try the next best thing - let's see if the Oilers twitter account will reply if I ask them. I can't find any of their EQM's on twitter - Jeff Lang, Brad Harrison and Shane Olmstead.

colins

-

26 minutes ago, stick9 said:Having spoken to an EQM at the AHL level. He tells me there are a good number of players who have no idea what they are skating on. They simply hand their skates to the guy who does the sharpening. He did say there are some guys who are fanatic about it, but nothing like you see at the retail level.

Again, I don't think it's an major factor. If you believe that, then you have to believe that he wouldn't be the same player on a different ROH, and that's just crazy.

At the retail level (I don't work retail, but I speak to a lot of hockey parents who take their kids skates to get sharpened ) I would suspect it's the opposite - lots of consumers have no idea there's even a choice, and they just want "sharp edges" which usually gets them 1/2" or 5/8" depending on the shop.

I think McDavid would be an elite player on any ROH, with any flex stick and any curve. But I don't think any of the top of the top of the elite players in the league fit into the category you describe w.r.t not knowing what hollow they are staking on. Maybe 3rd & 4th line players in the AHL, but you don't become elite by not having attention to detail.

McDavid likely has a preference for hollow, and the question is (and remains), what is it?

colins

-

6 hours ago, flip12 said:I was wondering if you were thinking of this before, but it sounds like you're on the "Linear Crossover" topic. I'm actually quite skeptical that this works the way that the guy who's always pushing it describes. It is a powerful weapon for attackers, but it's not all about top end speed. If it were you'd see guys taking linear crossovers when they get their first step out in the open on a breakaway. Also, the guy with the best speed today might still be Grabner and he hardly ever takes crossovers. He just outskates everyone on the ice and with a lower stride rate to boot.

Yes, I agree with everything you said here. We're speaking crossover to stride ratio w.r.t speed in the context of the offensive side of the game of hockey - which as you point it is all about seeking/attacking open ice and pressuring defenders to change direction.

Skaters that rely on deep knee bend wide extension (like Taylor Hall for example) have incredible straight away speed which works really well when they have clear open lanes. But that is rarely the situation for forwards in a 60 min game of pro level hockey. In the Robby Glantz breakdown video I think Eichel runs out of room once the defender Sekera closes the gap on him. If he takes another stride his skates are going to hit Sekera's skates and his rush will be over - so he spins to keep the play alive. McDavid usually can keep striding at very high speed even as the gap closes because his stride (especially during crossovers) is realtively short and he'll crossover in tight space to increase the gap without any hesitation (head, hands or feet).

Grabner as you mention is another interesting case - I haven't watched him nearly enough to have a full understanding, but it seems to me his secret sauce is his stride frequency. He just seems to return his extended leg under his body quicker than most skaters can.

McDavid's technique (and I think Bure was similar) allows them to maintain top speed while continually seeking/creating new space. For the game as it's played today, I would suggest this is the most useful type of speed/techique to have in your toolkit. Few can do it like McDavid can. Kids today should be learning this from an early age - a lot of traditional 'power skating' I've seen while my kids have grown up in the game don't have nearly enough emphasis in this area.

Great discussion - all the best,

colins

colins

-

1 hour ago, DarkStar50 said:I believe pros skate more alike than you may think. The best place to watch a pro skate is behind the goal line. Watch any NHL skater perform a C cut breaking out of his zone as you watch his stride from the ass end and think what you may have in common with him. Sorry, but for most of us, probably not much. And if you really want to have some fun, google any Youtube clip of Paul Coffey from the 80s power skating(that would be without lifting either leg off the ice, just shimmying his hips from side to side like elite figure skaters do for speed before jumps) goal line to goal line to see how stride and technique take professional hockey and figure skaters apart from everyone else.

McDavid and Eichel are very different skaters at a technical level. They are both elite, but the manner in which they achieve their elite status is very different. There are many shades of gray in between. Coffey was a treat to watch and I still like looking at video of the way he skated.

Robby Glantz does an excellent breakdown of Eichel and McDavid here:

colins

-

2

2

-

-

25 minutes ago, stick9 said:I don't thinks it's all that big of a factor. I'm willing to bet guys simply skate on whatever they are familiar with. I don't believe they look to it as a performance gain or loss. I can see them saying to the EQM "skates feel a little dull or a little too sharp", the EQM tweaks the hollow and asks "is this more what you're looking for".

Do I think Connor McDavid could skate the way he does on both a 1/2" OR a 1" ROH if we had two pairs of his skates and asked the EQM to swap them between shifts? Yes, I do.

Do I think Connor McDavid cares what specific hollow he has on his skates when it's game day? Yes, I do.It is a big factor in that every player only has ultimate trust and confidence when they have things set the particular way they want them. That's true at the beer league level, and even more so at the pro level. So back to the original question - what's McDavid's preference w.r.t. skate hollow? We're still waiting for that answer.

If you read stories on Coffey and what he used to ask Barry Stafford for, it's evident some of the greatest skaters in the history of the game were constantly looking for improvements to what we'd assume was an already perfect situation. Coffey, Bure, McDavid - they all share something in common with the way they moved their feet - they rarely took more than a couple strides before utilizing a crossover. Today's best skaters are the ones with a high crossover to stride ratio. Coffey did it on a 1" ROH http://edmontonjournal.com/sports/hockey/nhl/cult-of-hockey/the-nhls-best-players-pushed-stafford-the-hardest-the-oilers-way-pt-4

colins

-

4 minutes ago, DarkStar50 said:End of the day, there is how we skate and there is how pros skate. Sorry folks, ROH has nothing to do with it. Those guys flat out know how to skate.

Pros skate a hundred different ways. I still find this analysis interesting. ROH is a factor - but just like stick flex and stick length, there's no single answer to the question of what's "best".

-

18 hours ago, markush said:Just interested to know - does anybody have information about that?

I don't know, and can't find it published anywhere, but I'm guessing he's on 1/2" or deeper. Reason being is that his speed is all driven by crossovers. I'm assuming to get the force he does on both inside and outside edges when crossing over he's more interested in bite than glide.

colins

-

1

1

-

-

7 minutes ago, bootsmagee said:Finally got around to taking a few pictures of my storage/travel solution. I used a Jr. Sherwood rolling goalie bag ($80 on ebay) and 1" black polyethylene foam sheet. I used hot glue on the poly-to-poly seams and Sprayway 92 trim adhesive on the poly-to-bag areas. Funny, there's lots of visible adhesive overspray in the flash of the pictures but it's literally not visible at all in person, I swear

. I cut about 4" out of the goalie bag and sewed it back together, so it's 4" shorter than it would normally be when laying on the ground. If you look closely at the seam along the perimeter webbing, you can see that it's not perfectly straight from where I sewed it back together. The Sparx fits pretty snugly, so I use those two straps to lift it out more easily from the top.

. I cut about 4" out of the goalie bag and sewed it back together, so it's 4" shorter than it would normally be when laying on the ground. If you look closely at the seam along the perimeter webbing, you can see that it's not perfectly straight from where I sewed it back together. The Sparx fits pretty snugly, so I use those two straps to lift it out more easily from the top.

Awesome setup. Do you take it on the road, or just back and forth from home and the local rink? Are you using an edge checker, if so which one?

colins

-

1

1

-

-

I have the Sparx edge checker. It's sturdy and works really well. On LS3 steel I get consistent readings tow to heel or heel to toe. It's allowed me to really dial in my alignment on my sharpener for measurably perfect edges.

I also have the Edgechecker.com edge checker. I like the design but I find the magnet area on the back piece that attaches to the side of the blade is too tall, even with brand new LS3 steel, and this causes it to sit high up on the blade, making the level front piece read from the bottom two lines of dots. It's obviously a much cheaper piece of equipment, the 'dot printout' on the back piece itself seems a little low tech and mine doesn't appear to be stuck on perfectly level to begin with. But it gets the job done and is half the price of the Sparx unit.

If I was going the cheaper route again and had my time back I'd try the Prosharp edge checker. Similar design as Edge Checker, but a higher tech version, and it appears the magnet on the back piece is nice and shallow which should sit well on any blade, even those that are well worn down. $65 in Canada, $49 in US. https://prosharp.ca/collections/accessories/products/test or https://prosharp.us.com/collections/accessories/products/test

colins

-

11 hours ago, Chadd said:I've always said that caring about the quality of your work is the most important part of being a good sharpener. Oddly enough, I find most of the really good sharpeners are also the least likely to brag about it.

15 hours ago, DarkStar50 said:I'm not going to say skate sharpening is easy but I don't agree with this idea that it takes years to master. It is a skill that takes practice to get started, confidence in your ability, and a work ethic to do the job right every time. Like any job, it is a matter of caring about what you do. It's not rocket appliances.

I think it requires a certain aptitude to be done well. I don't know that everyone possesses the attention to detail required to do it well and do it well consistently.

colins

-

17 hours ago, IPv6Freely said:I've been extremely happy with mine. To go along with what @bootsmagee mentioned, not having an adjustment period after a fresh sharpen is wonderful. Although in my case the adjustment wasn't from the wrong hollow so much as just going for so long without getting them done that they felt night and day when I'd eventually get them sharpened. So that's where the consistency thing comes in for me.

I have absolutely no doubt that an expert sharpener would do a better job overall. But since I don't have one of those near here, I will take the consistency knowing what it will feel like every time I step on the ice any day. And even if I did have one nearby, I still like that I can do mine before every skate (even if sometimes it's just 2 passes). So really, even if an expert sharpener was available, I'll still take the convenience and consistency any day.

If I wasn't a beer leaguer I might feel differently and want the absolute best no matter the cost or convenience, but for me this is just a better option across the board.

I'm on my 2nd 1/2" ring and still have about two-thirds life left on a 5/8" ring. I picked up an edge checker about two weeks ago - now that I've edge checked all my steel and made a one or two click adjustment on my alignment to really dial in my edges to less that .001" difference in height, I can't say I'm lacking anything on my Sparx sharpenings vs. taking them to a pro shop now. It's damn near perfect.

colins

-

15 hours ago, Vet88 said:"Because the base layer is protected the abrasive" - I'm kind of struggling to understand this sentence. Lets assume it was meant to be "Because the base layer is protected by the abrasive" then it isn't really talking about the abrasive at all. It's talking about the base layer. I'd expect the base layer to retain its shape, it's the profile of the abrasive after 200 passes that I would be interested in.

But on the other hand lets assume somehow the sentence is about the abrasive and it's profile is always "PERFECT". As an engineer who has spent a lot of years working with abrasives I find this particularly hard to swallow. You have a product that by the very nature of its work wears away every time it is used. Let alone the fact that the entire surface of the profile of the grinding wheel is not in contact with the skate blade (the outer edges do not contact, do these just mysteriously evaporate away?) you have minute variations in the shape of the hollow of the blade that causes + / - grind resistance as the wheel does it work. And if you ever changed your hollow then this would only magnify the issue.

Otherwise what they are saying is they have invented an abrasive that never changes shape during it's life span, its wear is even and consistent REGARDLESS of the shape of the surface it is in contact with. If this is the case then they are wasting their time making skate sharpeners, I can think of a dozen better applications they could put this technology to use with...

I guess what you're asking for, and what we're all curious about, is a comparison of a brand new Sparx ring with a ring that has 300+ passes on it. It would be interesting to have measurements and high res images of the two for comparison purposes. The claim is that with the Sparx rings, you can get 320 passes before wear becomes an issue / the change in profile is significant enough to care about.

colins

-

17 hours ago, Vet88 said:How do you check the grinding ring for accuracy of hollow after x sharpenings? Using other sharpening systems one would dress the wheel before sharpening the blades (either to change hollow or to ensure the wheel was still true at it's setting) so how does sparx retain the accuracy of the hollow on the grinding ring?

You can't. You get 320 passes from a ring then it's done. It's not a traditional ring, as per their FAQ. Whether the radius of hollow changes at all during the course of using it during it's 320 pass lifetime is a good question. Maybe the Sparx guys can chime in and show some measurements from a new vs. fully used ring to demonstrate how the ring wears over time.

- Why doesn't the Grinding Ring produce sparks?

- The most significant factor is the grinding ring used by Sparx. Our grinding ring is made with a completely different material than a traditional grinding wheel. We're using a synthetic diamond abrasive. This different abrasive material results in a cooler sharpening process and also a cooler swarf.

- How does the hollow stay consistent?

- The Grinding Ring construction is a steel base material that is precision machined to the specific profile (e.g. radius of hollow). The base material is then coated with an abrasive layer. Because the base layer is protected the abrasive, its shape is not altered during the sharpening process (i.e. the profile is perfect on the 1st and 500th pass)

-

16 hours ago, Chadd said:If you're using one of those, you aren't doing it yourself. That's like saying you "cooked dinner" when all you did was put something in the microwave.

That's not a fair comment. The skills required to operate a Sparx are certainly less than a traditional machine, which is a good thing. But you still have to know what you are doing.

It doesn't matter how fool proof something is - there's got to be folks with Sparx machines that are not paying attention to alignment, ring height, skate positioning in the clamp, the required number of passes and honing technique and yes - they'd end up with imperfect edges. That's not a knock against the machine, it's a knock against human nature and folks who pay attention to detail vs. those who don't.

I know of an 'expert' sharpener (guy's been at it for years, also does equipment repairs) who uses multiple Cag One machines in his shop. Easy to use, right? Just lay the skate on it. Well he doesn't bother to use an edge checker (slows down output, he's very busy), and when one of his machines goes out of alignment, a whole crew of folks go through there with uneven edges on one skate until someone calls it out.

Again, the Sparx is just another machine. It makes the process simpler and lowers the cost to entry, but it's not 100% fool proof. But because it exists, a thousand new sharpeners are now active across North America, and I imagine a similar (or higher since the machine is easier to use) percentage of those new sharpeners are good at what they do vs. the ones that existed before Sparx.

colins

-

1

1

-

Sparx Skate Sharpener - At home sharpener

in Ice Hockey Equipment

Posted · Report reply

I always use the goalie risers (the orange plastic pieces) when sharpening new LS3/4 and Step Steel on my Sparx. Since those blades are taller than most steel, I find the ring has a bit too much pressure on the blade unless you use the risers, or raise the skates up higher in the clamp (taking the weight off the holders - this is tricky because it's harder to level then). I still put the height adjuster at 6 or 7 to hit high up on the radius - the risers work great for tall steel in general not just goalie steel.

colins